| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

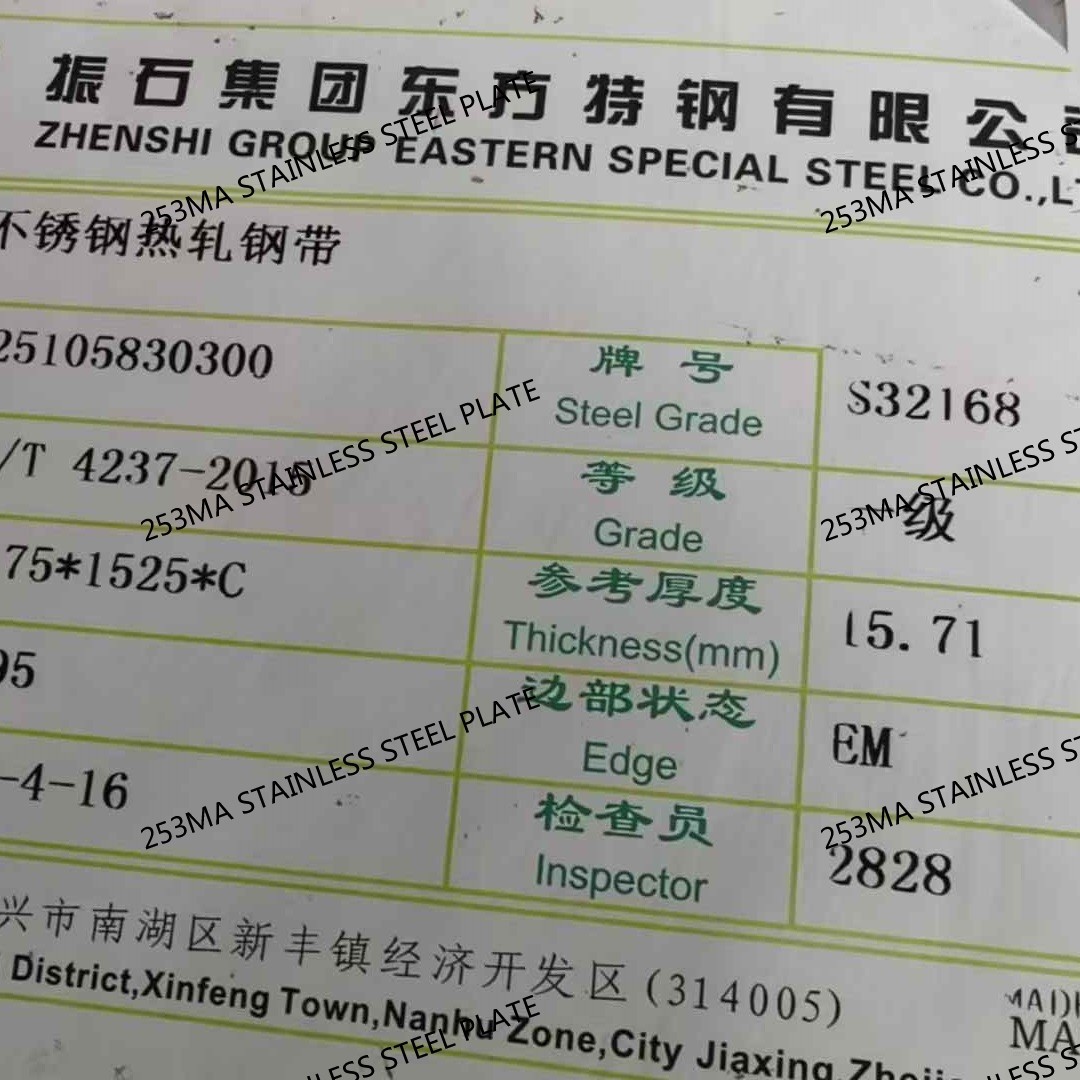

Brand Name : TISCO BAOSTEEL

Model Number : 253ma / S30815

Certification : ISO

Place of Origin : China

MOQ : 500 kgs

Price : 1700- 2000 USD/Ton

Payment Terms : T/T, Western Union

Supply Ability : 20Ton per week

Delivery Time : 5 - 12 days based on the quantity

Packaging Details : standard packing for export

Products : Stainless Steel Plate

Grade : 253ma / S30815

Thickness : 3.0 - 80.0mm

Width : 1500mm 1800mm 2000mm

Surface : NO.1

Brand : BAOSTEEL TISCO

Standard : ASTM A240/240M

Loading Port : Shanghai Port

253MA Stainless Steel Plate Heat Resistant up to 1150°C, Ideal for Heat Treatment Equipment & Exhaust Systems

Products Specification

| Products Name | 253ma Stainless Steel Plate |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,253MA,2205,2507.etc |

| Thickness | 3.0 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

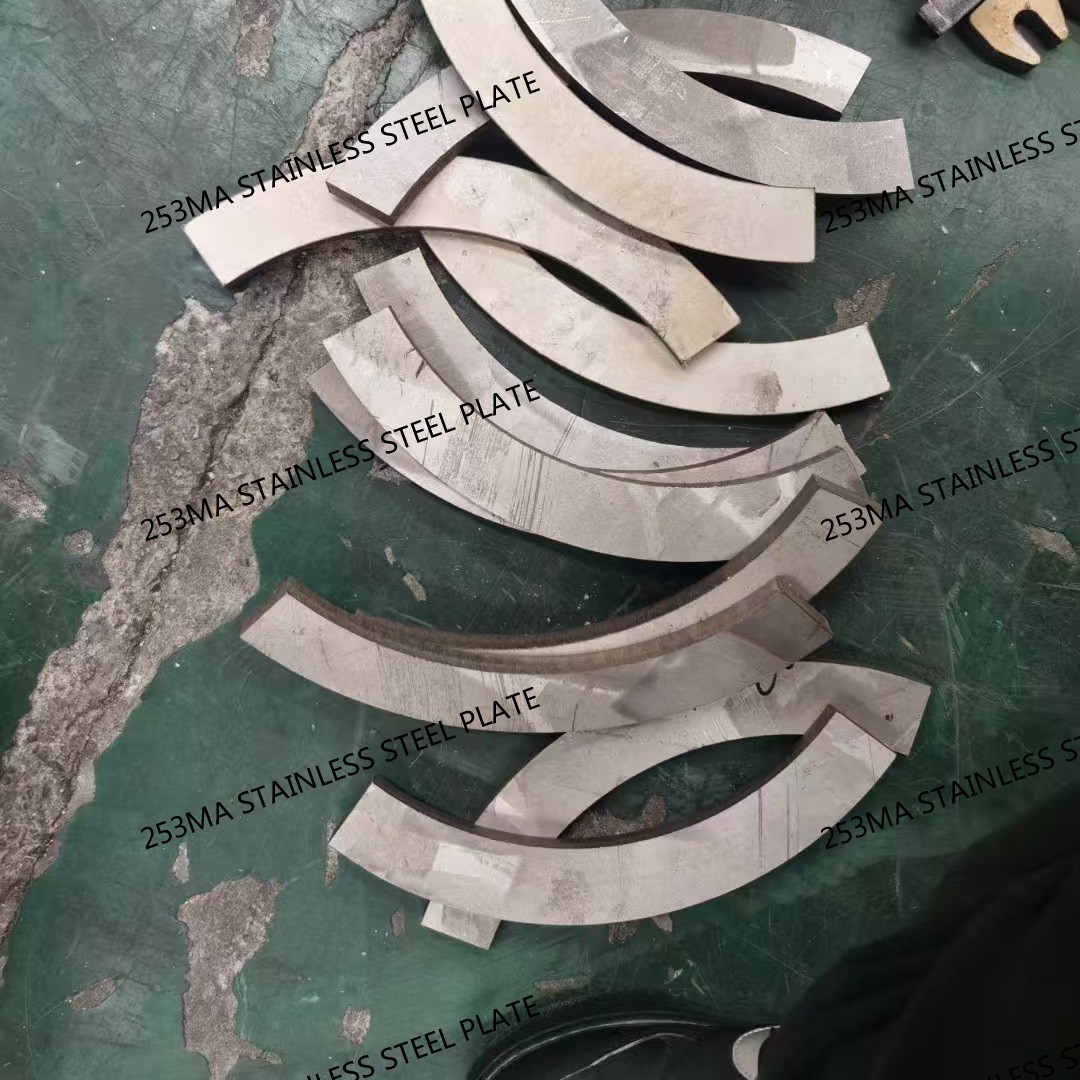

| Type of Material | Laser Cutting |

| Form | Plate / coil |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

253MA® is a patented, nitrogen-enhanced austenitic stainless steel engineered by Outokumpu for extreme thermal cycling environments (up to 1150°C/2100°F). Its cerium micro-alloying forms self-healing oxide layers, delivering superior oxidation/spalling resistance versus 310S/309S grades. Ideal for cost-sensitive replacements of nickel alloys in corrosive, high-stress thermal applications.

| Parameter | Value |

|---|---|

| Chemical Composition | |

| Cr | 20.0–22.0% |

| Ni | 10.0–12.0% |

| N | 0.14–0.20% |

| Ce | 0.03–0.08% |

| Mechanical (Annealed) | |

| Hardness (HV) | ≤ 230 |

| Impact Toughness (20°C) | ≥ 100 J |

| Thermal | |

| Thermal Expansion (20–1000°C) | 16.5 μm/m·°C |

| Thermal Conductivity (600°C) | 26 W/m·K |

Material Standards:

ASTM A240/A480 (Pressure Vessel)

EN 10095 (Heat-Resisting Steels)

ASME II Part A (Boiler Code)

Certifications:

EN 10204 3.2 Certification

NORSOK M650 (Oil & Gas)

ISO 3834-2 (Welding Quality)

| Attribute | Details |

|---|---|

| Thickness | 0.3 mm – 150 mm (Custom >100 mm) |

| Width | 600–2500 mm (Tolerance: ±5 mm) |

| Surface Finish | New: N4 (Brushed), HL (Hairline) |

| Form | Quarto Plates, Precision-Shim Stock |

| Tolerances | EN 10029-1.4301 Class A (Thickness) |

Anti-Corrosion Packaging:

3-Layer Protection: VCI Paper + PE Film + Desiccant

Sealed Edges with Silica Gel Capsules

Export Security:

Steel-Banded Waterproof Wooden Crates (IP67 Rating)

RFID Tracking Tags + QR-Coded Labels

Custom Options:

Vacuum-Sealed Units (For Aerospace)

Non-Marking Rubber-Separated Stacks

| Industry | Specific Use Cases |

|---|---|

| Energy | Advanced-Ultra Supercritical (A-USC) Boiler Tubes |

| Aerospace | Afterburner Components, Exhaust Systems |

| Hydrogen | Electrolyzer Hot-Box Components |

| Additive Mfg | Powder Bed Fusion (PBF) Base Plates |

| Nuclear | Gen IV Reactor Heat Exchangers |

vs. 310S: 30% higher creep strength at 1000°C

vs. Alloy 800H: 40% cost reduction with comparable oxidation resistance

Unique Capability: Withstands cyclic sulfidation in waste-to-energy plants

Fabrication:

Laser Cutting: N₂-Assisted for Oxide-Free Edges

Post-Weld Heat Treatment: 1100°C Water Quench Required

Compliance: REACH SVHC-Free, RoHS 3 Compliant

Disclaimer: 253MA® is a registered trademark of Outokumpu Oyj. Properties valid for solution-annealed condition. Contact for cryogenic (-196°C) performance data.

|

|

253MA Stainless Steel Plate Heat Resistant Up To 1150°C For Heat Treatment Equipment Exhaust Systems Images |